Home Page › Forums › Modeling the Missouri Pacific, Texas & Pacific, etc › HO Scale › MP 13515-13664 EV Caboose Models › Reply To: MP 13515-13664 EV Caboose Models

@cduckworth wrote:

Ryan

Can you post some photos of the parts and caboose kits?

The fourth link in the original post has the photos of the caboose parts I’ve received. There are so many of them I thought it would be easier to just give the link to the gallery rather than post them inline in the message.

Here’s the link:

http://www.pbase.com/mecrharris/3dprint_caboose

And here are some additional renderings and photos of other things, including some cupolas:

http://www.pbase.com/mecrharris/3d_models

When you click on any single image in the galleries, it will display a new page for that image. Scroll down below the image and you’ll see the exif info for the photo. Just below that you will see the text, “other sizes: small medium large original”. I’d recommend clicking original on these images so you can see the parts in all their glory.

For most of us who have seen 3D printed parts over the years, these parts will change what you think about 3D printing. It’s not “there” just yet, but brother it is getting a lot closer. It’s really amazing what can be done. These carbon black outlet covers are very small and the detail is even better than you can see in this photo, now that I know how to clean the parts better and avoid marring the details with aggressive solvents:

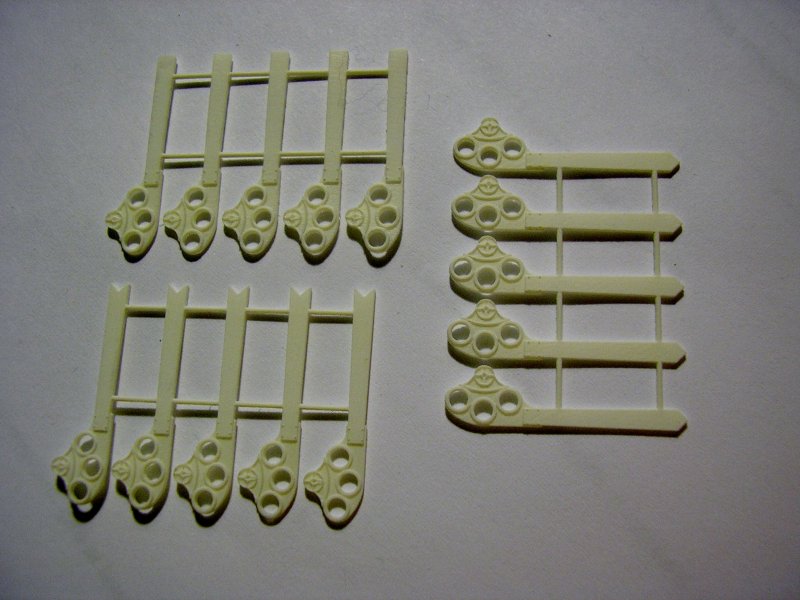

Some of my favorite parts are the semaphore blades. I’m working on a prototype double head semaphore mast mounted on a signal bridge. Still a ways to go on that project, but the semaphore blades themselves are done. Here they are in Frosted Extreme Detail:

As far as the caboose parts are concerned, again I’d recommend just browsing the gallery looking at the original images. I took the photos in the sequence shown and the first few photos are as I removed the parts from the bubble wrap, so they still have the waxy support material on them. As you go through the photos, you’ll see the parts as they are cleaned and the detail begins to be revealed. I go through the assembly process, which is very quick. The parts shown do not include the grab iron ends and drill starter holes that are now standard on all the sides. I’ve also made some revisions to the cupolas so the opening on the inside lines up with the underside of the roof (the ceiling from the point of view of the caboose occupants). I’d like to make some interior detail parts in the future, so this latest revision to the cupolas allows for that.

Speaking of revisions, I’m constantly trying to improve the parts. Since these parts are not the result of expensive tooling, they can be revised very easily and with no loss of investment. All I have to do is draw the changes to the part and upload the revised CAD file. As the technology improves, the possibility exists for me to thin out the parts that have been beefed up to meet the minimum thickness, such as the overhanging roof edge, or simply not included at all because it can’t be printed, such as brake stands and the plumbing at each end of the caboose.

Anyway, I think in spite of the cost, the technology is finally catching up to our hobby. We are rapidly approaching a point where having a critical mass of pre-orders or committed buyers isn’t a requirement to make unusual models anymore, even in the small runs we’ve seen in brass or resin. I made both the Cotton Belt C-40-8 and C-40-9 classes of caboose just because I want one of each and because I can. Surely either one would have satisfied the Cotton Belt modelers out there who wanted an alternative to the Atlas caboose. But why not have both? And the same is true of the Missouri Pacific cabooses I’ve modeled here. One version is good, but all versions are better! I didn’t do it because I have to get a certain number of sales to break even. I did it because I want one of each!

As more people develop the skills to translate our favorite prototypes to CAD files, we all benefit from the ability to recreate even the most obscure of our favorite prototypes in miniature. I understand the religious fervor of some when it comes to 3D printing; it’s a very exciting technology. Yes, it’s a little pricey now, but like laptops and flatscreen TVs, it’s going to get better and cheaper as time goes on. But right now, as it is today, it’s really quite good. I can’t tell you how excited I am to build all these projects!

Ryan Harris

Fort Worth, TX